why ccus

Tomorrow’s Technology Today

We are setting goals to transition our energy system so that we are living in ways that will be sustainable for generations. The Government of Canada has set a goal for our emissions to be net-zero by 2050.

As a first step, Canada has a target to reduce emissions by 40-45% below 2005 levels by the year 2030. This means reducing emissions from all sectors and all activities by around 300 million tonnes of CO2 each year from where we are today!

How do we get there? One of the biggest opportunities to get emissions out of our atmosphere is to capture and sequester them—underground or in products—permanently.

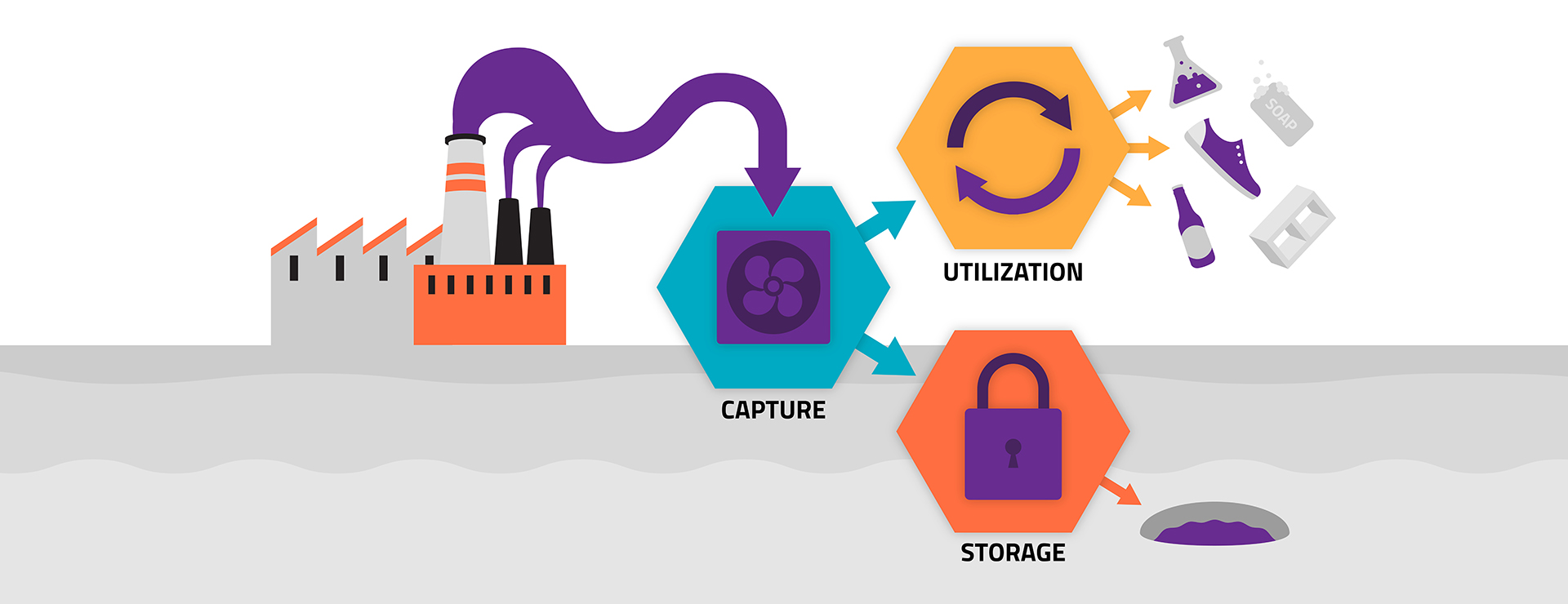

How does carbon capture, utilization and storage work?

Carbon capture, utilization and storage (CCUS) is a multi-stage process with the potential to have a big impact on Canada’s greenhouse gas (GHG) emissions reduction efforts. CCUS is an imperative technology for the world’s net -zero goals and Alberta has what it takes to be a global leader in this growing sector because of its unique geological landscape, existing energy infrastructure and skilled energy workers.

What is CCUS?

Did you know?

CCUS is a tested, proven and innovative solution to GHG emissions reduction. As a complex industrial sector, CCUS requires established processes, advancing technologies and a variety of skilled and knowledgeable workers. The sector is made up of five different stages.

Explore the dynamic CCUS sector in more detail through this interactive infographic.

Measurement, Monitoring and Verification

Now that CO2 has been captured and stored underground, how do we know it stays there safely?

Measurement, monitoring and verification (MMV) is a critical function in the CCUS process. After CO2 is injected into an underground formation, multiple steps are taken to ensure that it is monitored and stays there safely.

CO2

Jaeson Cardiff, CleanO2

Capture

Brent Henkel, Svante + Blake Adair, Nutrien

CO2 capture is the process of separating, purifying and compressing CO2 to make sure that industrial emissions aren’t entering the atmosphere. There are many different types of CO2 capture technologies that can be applied to many different industries such as heat and power generation, hydrogen production, steel, cement or chemicals. In order to reach transportation or utilization quality, the CO2 may undergo some further processing to make sure it meets specifications.

Capture

Brent Henkel, Svante + Blake Adair, Nutrien

CO2 capture is the process of separating, purifying and compressing CO2 to make sure that industrial emissions aren’t entering the atmosphere. There are many different types of CO2 capture technologies that can be applied to many different industries such as heat and power generation, hydrogen production, steel, cement or chemicals. In order to reach transportation or utilization quality, the CO2 may undergo some further processing to make sure it meets specifications.

Utilization

Cailee Ellis, Lafarge + Lukas Deeg, Capital Power

Sequestration

Candice Paton, Enhance Energy

Sequestration

Candice Paton, Enhance Energy

Permanence

Marie Macquet, Carbon Management Canada

Measurement, monitoring and verification (MMV) are some of the most important activities in the carbon value chain to confirm that CO2 sequestered in underground reservoirs is stored permanently. By monitoring the air, soil, water and the underground storage formations – such as saline aquifers and depleted oil and gas reservoirs – we gather scientific evidence that the CO2 that we inject is stored securely in the injection zone. Carbon isotope testing can identify if molecules of CO2 observed in different layers in the subsurface are from anthropogenic sources (the captured CO2 ) or naturally occurring CO2 unrelated to the sequestration project.

Imagine what is possible when we work together.